4 Ways Phunkshun Wear Focuses on Environmentally Friendly Practices

PSIA-AASI Official Supplier Phunkshun Wear’s line of outdoor gear is popular among snowsports instructors for its all-season versatility. The Colorado-based brand is also popular for using sustainable and environmentally friendly manufacturing practices.

“We were the first face gear brand to start using recycled polyester in every product we make, back in 2014, and sustainability has remained a core fundamental value for our brand,” said Phunkshun Wear Chief Executive Office Jason Badgley. “Sustainable domestic manufacturing is important to our brand, it’s part of our DNA.”

Here are four key ways the brand is working to produce superior products while lessening their environmental impact:

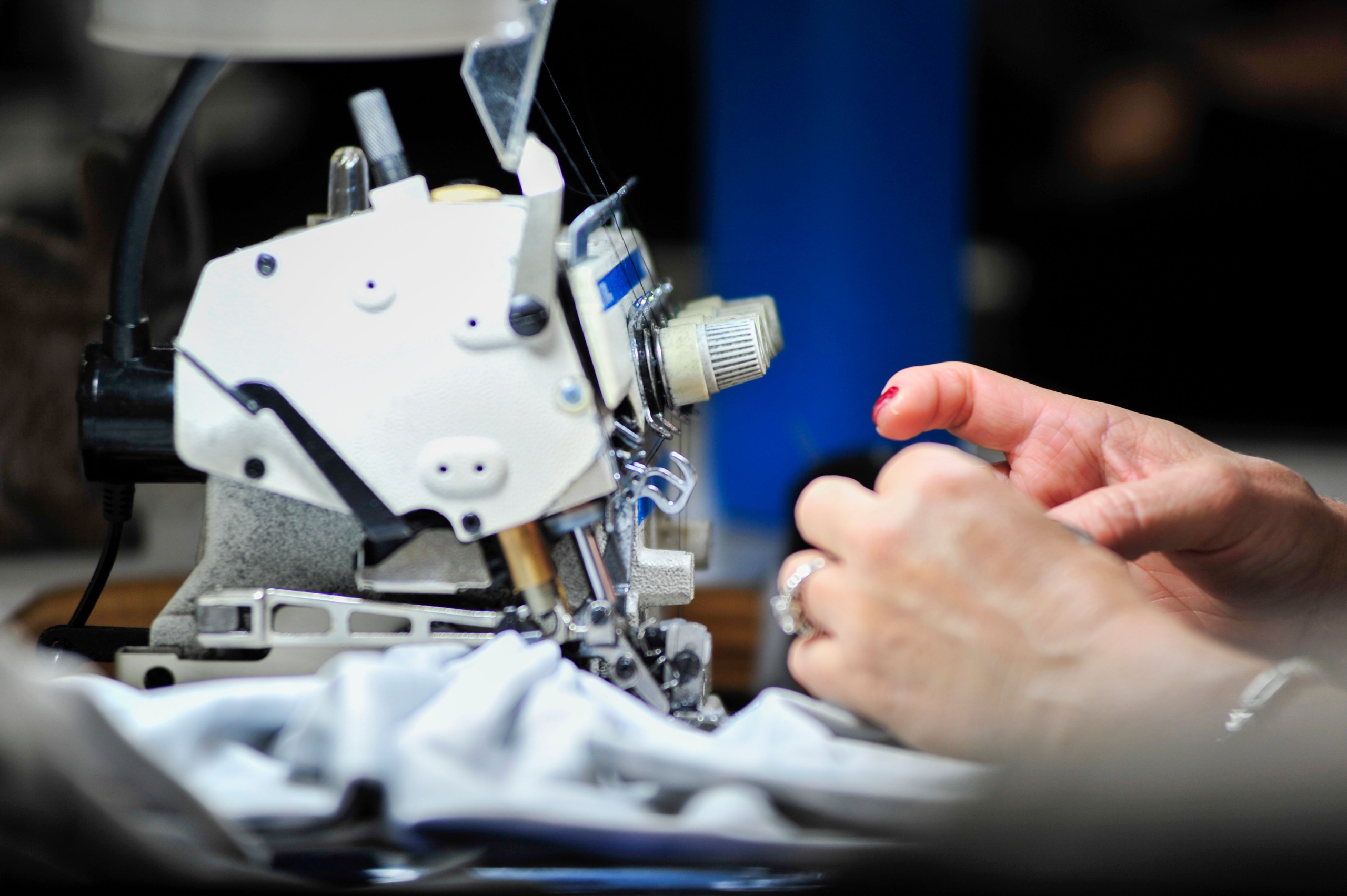

- Phunkshun Wear is part of a pilot recycling program with Waste Management of Colorado in which they recycle, on average, 900-pounds of fabric scrap a month, which is then reused.

- An average of six recycled bottles are used in each product! The plastic bottles are collected in the USA and instead of ending in landfills, they are processed by Unifi® and made into Repreve® Recycled Fiber. Yarn is milled domestically and knitted into fabric before being transported to Phunkshun Wear’s production plant.

- The manufacturing process begins in Phunkshun Wear’s Dye Sublimation Print Room, which produces virtually zero waste through recycling and conservation initiatives.

- Phunkshun Wear is actively identifying areas for further reduction of single-use plastic while also investing in locally manufactured, recyclable packaging for their products.

Treat yourself to member-specific pricing on Phunkshun Wear products.